ーNewsー

Jun. 5. 2021

A review paper on liquid crystal lubricants was published in the June issue of "Lubrication Economy.

Contact: Yuichiro Haramoto (Doctor of Engineering, Professor Emeritus, University of Yamanashi)

Email: haramoto@i2.gmobb.jp

ーWhat is "Liquid crystal lubricants"ー

〜World's first lubricating material with various advantages〜

Liquid crystal lubricants are the world's first lubricants that provide the following properties

①No loss due to evaporation (zero weight loss even after heating at 100°C for 2000 hours)

② High heat resistance

③ Machine durability can be improved by 2.5 to 40 times.

④ Less dust generation

Nippon Thompson Co., Ltd. (6480.T) was the first company in the world to introduce liquid crystal lubricants into linear motion guiding equipment and bearing products, and has been developing a series of liquid crystal lubricants such as "Liquid Crystal Lubricated Linear Way".

It can be applied to a wide variety of machinery, and simply replacing existing lubricants with liquid crystal lubricants can significantly improve the durability and performance of machinery.

Why don't you work with us to improve the performance of your products?

ーStructure of Liquid Crystal Lubricantsー

Here is the structure of the liquid crystal lubricant.

(1) The structure of the lubricant is incorporated into both ends of the liquid crystal molecules.

(2) Liquid crystal lubricant molecules form a molecular aggregate state called smectics by self-assembly.

(3) Liquid crystal lubricants form an aggregate of 100,000 to 10 million molecules as shown below, and lubricant structures are tightly lined up on the upper and lower surfaces of the aggregate.Lubrication is achieved by the sliding of these aggregates together.

These enable the aggregates to lubricate metal surfaces with strong protection, which greatly improves the durability of machines and other equipment that use liquid crystal lubricants.

ーProperties of Liquid Crystal Lubricantsー

Learn about the benefits and properties of liquid crystal lubricants.

(1) No loss due to evaporation

Liquid crystal lubricants has no loss by evaporation even under high temperature. Even after 2,000 hours of heating at 100 degrees Celsius, the residual rate is 100% and there is no change in mass.

On the other hand, the residual rate of ordinary hydrocarbon-based grease decreases to about 90% after 500 hours, confirming the superiority of liquid crystal lubricants.

(2) High heat resistance

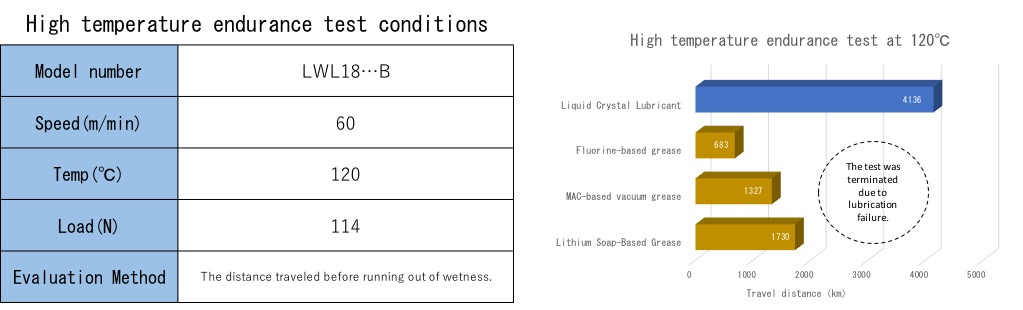

As a result of a high temperature endurance test at 120°C, it was found that the liquid crystal lubricant can travel 2.5 times longer than other lubricants, indicating that it has high heat resistance.

(3) Possible to improve the durability of machinery

Since conventional lubricant molecules only exist in pieces as shown below, when a metal approaches from above or below, the molecules simply escape to the left or right, and the ability to prevent wear of the metal is very small.

On the other hand, liquid crystal lubricants form aggregates as shown below, and the aggregates resist the approach of the metal, resulting in a very high ability to prevent metal wear.

Because of these features, durability tests have shown that the durability of machines can be increased by 2.5 to 40 times when compared to the use of conventional lubricants.

4) Less dust generation

As a result of dust generation tests, it has been found that the amount of dust generated is 1/10 of that of commercially available hydrocarbon greases, making it possible to introduce this product into semiconductor manufacturing equipment, LCD and EL display manufacturing equipment, etc., where an ultra-clean environment is required.

ーContact Usー

If you have any questions, please feel free to contact us at the address below.

Functional Liquid Crystal Materials Laboratory

Address: Grandir Nihonbashi 3F, 1-33-4, Nihonbashi-Kakigaracho, Chuo-ku, Tokyo, Japan

Phone number: 03-6231-0796

Representative :Yuichiro Haramoto (Doctor of Engineering, Professor Emeritus, University of Yamanashi)